OVERVIEW

Project: Banksia Grove Residential Subdivision

Location: Carramar Western Australia

Client / Asset Owner: Banksia Grove Development Nominees

Consultant / Specifier: Cossill & Webley Consulting Engineers

Contractor: Brierty Contractors (Original install)

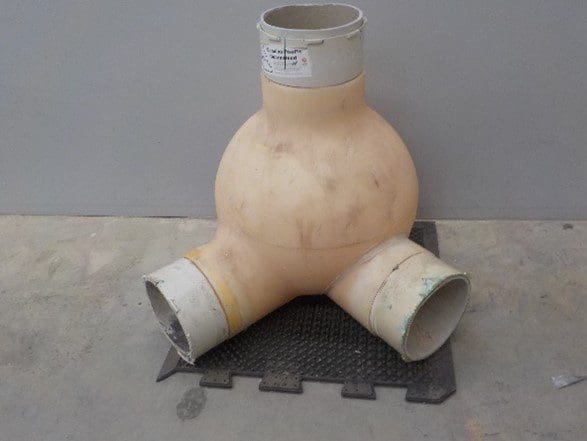

Product/s: Poo Pit Sewer Maintenance Shaft

PROJECT

Due to a design change at the site to facilitate new inlet, i.e., a new sewer coming in from the west required a new access chamber. The existing Poo Pit (Type 8 Sewer Maintenance Shaft) originally installed in 2007 was replaced with a new Poo Pit in 2022 to incorporate this new sewer design.

Available with DN 225mm or DN 300mm riser

- Built to suit solvent weld or rubber ring PVC

- Tested to Depth of 7.5m (Half Pit available for shallow installations)

- Achieves any angle between 65°-315°

With its intuitive design, the Smartstream Technology Poo Pit™ is revolutionising maintenance shaft installation. Use the Australian-manufactured Poo Pit™ in your next sewer, stormwater or subsoil drainage project for a safer, cost-effective installation.

AUSTRALIAN OWNED & INNOVATED

We are a wholly owned and operated, Australian family company and innovators in civil engineering infrastructure solutions using roto moulding and plastic injection technology, minimising concrete use, to produce a highly developed range of stormwater and wastewater products. We know the industry; we’ve been in it since 1984. We understand the challenges. We are dedicated to researching and investigating new processes and materials – once the industry’s alternative, our products are now fast becoming the product of choice.

REDUCE CARBON FOOTPRINT

Revolutionary, easier to source and customisable, Smartstream Technology products are now being used to reduce carbon footprint and future-proof infrastructure.

OPERATIONAL EFFICIENCIES

The vertical riser shaft is used for access and insertion of equipment into operational units. Combining the ease of at surface inspection, monitoring and maintenance together with its key characteristics of being corrosion resistant, lightweight and cost effective. The Mini Pit™ is the ideal choice for your next maintenance chamber installation.

STANDARD

Standard Water Services Association of Australia WSA137 – Maintenance Shafts and Maintenance Chambers Quality

QUALITY

ISO 9001 Quality Management Systems

FEATURES

- Lightweight

- Durable impact resistant polyethylene

- Custom fabrications to specific requirements

- Superior hydraulic performance

- Cost effective

- Compatible with all pipe materials, including PVC, PE, Polypropylene, Steel and Clay

BENEFITS

- Corrosion resistant – from hydrogen sulfide internal attack and acid sulphate external attack

- Watertight – no leakage; no infiltration and inflow

- Accommodates multiple inlets at any angle and grade

- Easy to retrofit into existing lines

- Faster installation

- Smaller carbon footprint compared to traditional access chambers

The existing Poo Pit’s successful performance over 15 years and its current ‘still fit for purpose’ condition confirms the Poo Pits ongoing suitability for this application. This pit services 22 residential housing lots and based upon the Water Corporation of Western Australia’s design criteria, it is estimated that this pit has had 2.148ML of effluent flow through it during its 15 years’ service life.

To our knowledge this is the oldest Poo Pit to be exhumed since Poo Pits were initially approved by the Water Corporation and first installed in Western Australia in 2001.

Since this time, it is estimated that approximately 150,000 Poo Pits have been installed without a single recorded failure.