and service all in

one place

Stormwater Pits for the

construction industry

built to

Australian standards

Search Civil Construction Products By Category

Who is SMARTSTREAM Technology ?

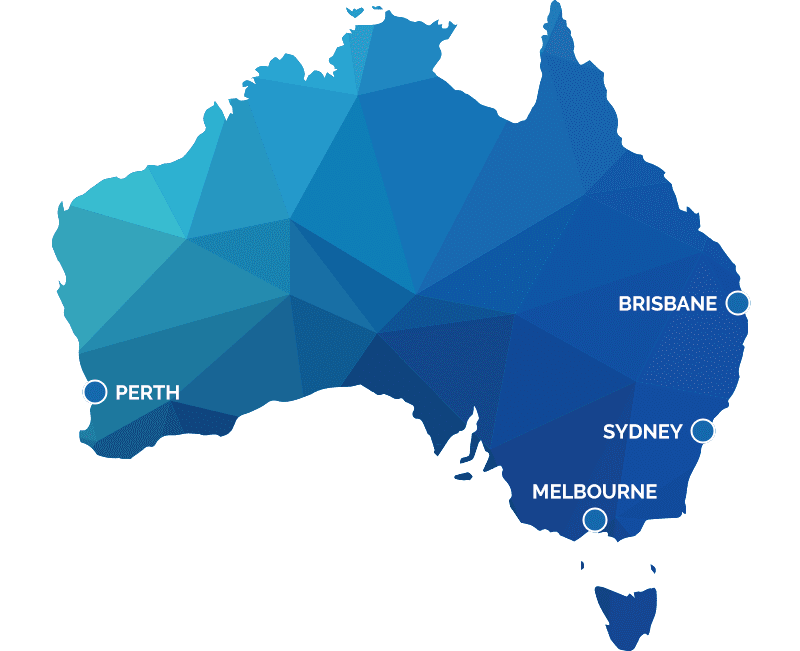

Welcome to Smartstream Technology, your trusted partner in civil engineering and infrastructure solutions. With over three decades of experience as an Australian-owned and operated business, Smartstream Technology has been at the forefront of manufacturing innovative products since our inception in Perth in 1984.

At Smartstream Technology, we are dedicated to continual innovation, constantly exploring new processes and materials to ensure that our products remain cutting-edge and beneficial for all building applications. Our commitment to quality assurance means that you can trust our products to deliver environmental benefits, job safety improvements, longevity, and faster installation times, all while staying within your project’s time and budget constraints.

Our track record speaks for itself, with over 200,000 successful Poo Pit maintenance shaft installations completed across Australia, New Zealand, Bali, Indonesia, and the US. This growth is a testament to our dedication to excellence and our ability to consistently deliver results for our clients.

By choosing Smartstream Technology for your next development project, you can save both time and money while ensuring that your project is completed on schedule and with the highest standards of safety. Our experienced and professional team is here to provide you with the advice and support you need to make your project a success.

We pride ourselves on being innovators in the civil construction industry, constantly pushing the boundaries of what is possible with our unique plastic and concrete products. If you’re ready to experience the Smartstream Technology difference for yourself, we invite you to contact us today to discuss your next project.

Together, we can build a brighter future with Smartstream Technology.

Our team can assist with solutions for your project needs –contact us today for an obligation-free quote

COMPANY VALUES

Our business is underpinned by family values, and genuine care for our clients, staff and stakeholders. We give everyone opportunity to succeed, grow and prosper.

We have a positive, “can-do” mindset and relentless drive & energy. We strive for better, every single day.

COMMITMENT TO QUALITY

Our quality standards are second-to-none. We have a number of certifications highlighting our quality standards.